Motors

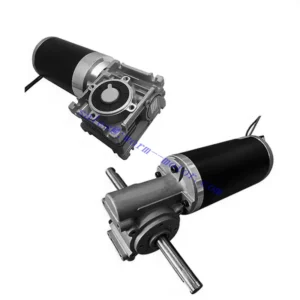

As one of the worm motor manufacturers, suppliers, and exporters of mechanical products, We offer worm motors and many other products.

Please get in touch with us for details.

Direct Current Motor

What is a DC Motor?

A DC motor is a type of electric motor that uses direct current as an energy source. It has two separate parts: the armature and the stator, which are connected by a rotary commutator. This commutator reverses the current between the rotor and the power supply, producing a steady rotational torque. There are two types of DC motors: brushed and brushless. Brushed DC motors apply current to the rotor through brushes, while brushless DC motors use permanent magnets to generate current.

DC motors are easier to install and maintain than AC motors. They are also easier to service than their AC counterparts. In addition, DC motors can easily replace industrial equipment. In contrast, an AC motor may require the entire circuit to be redesigned to accommodate a DC motor.

Types of DC Motors

There are many different types of DC motors. Some are used in homes while others are used in factories. They are used in fans, air conditioning systems, and printers. Some are even used in remote controlled vehicles. In addition, they are used in medical equipment. These are some of the most common applications of DC motors.

DC Motor Working Principle

DC motors work on the principle of electromagnetic induction, which states that a conductor within a magnetic field experiences a force. Permanent magnets and electromagnets are used in both large and small motors. The permanent magnets lose their magnetism during wear and tear, while the electromagnets energize when a current is passed through their core.

Current flowing through the rotor windings develops a magnetic field around the windings, which interacts with the magnetic field of the stator. This interaction generates a force that manifests itself as rotation of the rotor. According to the law of conservation of energy, the force must be opposed, and the back EMF of a DC motor provides opposition to the force.

The armature of the DC motor does not rotate when there is no load applied. When a load is placed on the motor, it starts to rotate, and a large amount of current flows through the armature. This is due to the low resistance of the windings. This causes a counter electromotive force (CEMF) that opposes the applied terminal voltage. This resultant force is called torque. The torque generated by a DC motor is measured in Newton-meters.

A DC motor works by energizing its rotor, which is usually composed of a copper wire wound around an axle. This rotor then rotates in a magnetic field and produces a torque. During this process, electric current is constantly flowing through the windings.

Applications of DC Motors

Each type of motor offers its benefits, generally speaking, there are a variety of applications for an DC motor. At home, smaller DC motors are employed in toys, tools, as well as various household appliances. In retail, the uses of DC motors can be found in conveyors as well as turntables. In an industrial setting, massive DC motors also have brakes and reverse applications.

Here are a few particular uses of DC motors:

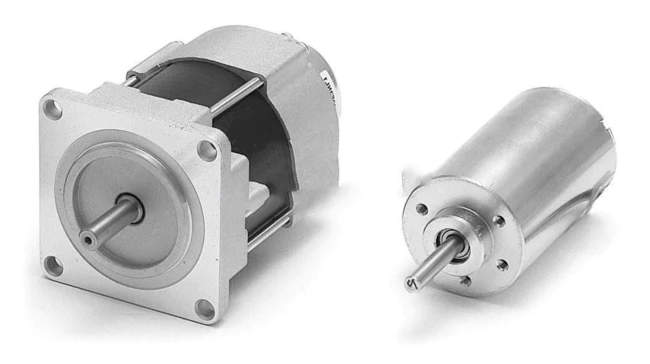

AC Motors-Asynchronous Motor

An AC motor is a type of electric motor that uses alternating current for power. It works by using electromagnetic induction, which is why it uses alternating current to drive its rotor. An AC motor has two main parts: a stator that is stationary and a rotor that rotates. It may be a three-phase or single-phase motor, depending on the type of work that it is intended to do.

Asynchronous motor is a kind of AC motor based on the interaction of air gap rotating magnetic field and rotor winding induction current to produce electromagnetic torque and realize energy conversion. Asynchronous motor is generally a series of products with a wide variety of specifications, and it is the most widely used among all electric motors with the largest demand; at present, about 90% of the machinery in the power transmission uses AC asynchronous motor, so its power consumption accounts for more than half of the total electric load.

The more common induction motors are single-phase asynchronous motors and three-phase asynchronous motors, of which the three-phase asynchronous motor is the main body of the asynchronous motor. The single-phase asynchronous motor is generally used in places where the three-phase power supply is not convenient, and most of them are miniature and small-capacity motors, which are more used in household appliances, such as electric fans, refrigerators, air conditioners, vacuum cleaners, etc.

Advantages of AC Asynchronous Motors

- Known for its high reliability and long service life

- All motors can be powered directly from the mains or inverter

- Highly versatile, available in various cooling types, protection classes and models

- Suitable for corrosive environmental conditions and hazardous applications

- Outstanding motor efficiency, optimal cooling

- Low operating costs guaranteed

- Flexible terminal technology for the feed line and the perfect synergy of all components

- Ensure safe and reliable operation of the entire motor system

Application of AC Asynchronous Motors

Asynchronous motor has the advantages of simple structure, easy manufacturing, use and maintenance, reliable operation as well as smaller mass and lower cost. Moreover, asynchronous motor has high operating efficiency and good working characteristics, from no-load to full-load range close to constant speed operation, can meet the transmission requirements of most industrial and agricultural production machinery. Asynchronous motors are widely used to drive machine tools, pumps, blowers, compressors, lifting and winding equipment, mining machinery, light industry machinery, agricultural and sideline processing machinery and most industrial and agricultural production machinery, as well as household appliances and medical equipment.

How do AC Motors work?

An AC motor has two main components – a rotor and a stator. The stator is a stationary element that contains six separate magnetic poles, while the rotor rotates with the rotation of the stator. At the beginning of the cycle, both the rotor and stator have opposite polarities, and when the two poles are attracted to one another, the rotor will rotate.

The AC motor is a specialized electrical generator that relies on an alternator. The alternator produces alternating charging direction by generating an electromagnetic field when electricity passes through the spinning shaft of the rotor. The rotor rotates in relation to the stator, and the resulting EMF is a force that switches direction at predetermined points.

The stator is the stationary part of an AC motor, and is made from two sets of red electromagnet coils. The current in the coils rises and falls in a sine wave pattern. This movement induces an electric current in the rotor, which in turn turns the rotor.

An AC motor is a common type of electric motor, but there are a number of variations on the basic principle. An AC motor operates on alternating current (AC). The AC supply reverses direction 50 times per second, or Hz.

AC Motor VS DC Motor

The choice between an AC motor and a DC motor depends largely on the application. For example, AC motors are less efficient than DC motors because they use electromagnets in the stator, which consume electricity. By contrast, DC motors use permanent magnets, which are much more efficient. AC motors also suffer from slip, which is the difference between the rotor’s speed and the magnetic field’s speed. This is crucial for producing torque, but it also contributes to power loss due to heat.

Another advantage of an AC motor is that it is lightweight and has precise speed control. This can improve travel time and smoothness. In addition, the AC motor has a lower cost, and can also offer faster start-ups. However, the conversion process from DC to AC is inefficient, and the benefits of weight reduction are lost in the process. However, power electronics have made the AC motor more reliable and cheaper.

The main differences between AC motor and DC motor include the size, structure, price, maintenance, and reliability. AC motors are more complex than DC motors, and their operating principles are quite complex.

Another difference between the two types of motors is the commutator. A DC motor has a commutator, which makes it easy to distinguish from an AC motor. The commutator is a very important component of a DC motor. Hence, it is important to understand what it is and what its advantages are.

Stainless Steel Gear Motors

Offers a complete range of sanitary-grade stainless steel anti-flush electric motors. All the stainless steel washdown duty electric motors are designed for harsh flushing environments and have inverter grades. technology is the pinnacle of sanitary design and is standard in all our motors. As one of the reliable stainless steel motors manufacturers and the exclusive manufacturer of technology products, we offer Stainless Steel Gear Motors which offers quality, performance, reliability, and enhanced cleanability.

Our stainless steel AC motors and reducers are designed for rigorous flushing applications with a smooth, hygienic finish for easy cleaning. The stainless motors come in various designs to suit multiple applications and are customized to your specifications. We welcome requests for unusual or custom work. Our engineering department will assist professionally in determining the best stainless steel electric motor and reducer combination to meet your specific requirements.

Food Safe Stainless Steel Washdown Duty Motors

The entire food safe range is designed with an advanced sealing system that has achieved an IP69 waterproof rating – the benchmark for products used in the sanitary sector. This classification means these products can withstand cleaning by high-pressure water jets commonly used in cleaning-in-place (CIP) procedures. The all stainless steel construction protects against corrosion.

The food safe stainless steel washdown motors and worm gear reducers feature encapsulated windings for longer life in harsh washdown conditions than general purpose products. These motors also eliminate the need for a motor shroud containing food particles and allowing bacteria to colonize. They are available in power ranges from 0.18-7.5 kw in 2-6 pole versions for 230-690 volts, 50 or 60 Hz.

Why Stainless Steel Motors are the Best Choice?

Stainless steel motors are easy to maintain, corrosion resistant, and easier to clean than traditional motors. Read on for more reasons to switch to Stainless Steel. Stainless steel is also paint-free, so your electric motor will last longer and be easier to clean. And don’t forget about the cost savings. Investing in stainless steel electric motors can save a lot of money on electric bills.

Stainless Steel motors are easier to clean.

A stainless steel electric motor is a far more hygienic choice for food manufacturers than aluminum or plastic alternatives. Because stainless steel does not have any coating, it is highly resistant to contamination and is not damaged by washing down under high pressure. Moreover, stainless steel is cheaper than other types of motors. In fact, stainless steel motors is the preferred option by most food producers due to its increased longevity and corrosion resistance.

The process of cleaning an electric motor can be time-consuming and can cause significant downtime. Often, cleaning a motor requires the motor to be completely disassembled. In addition, it is necessary to avoid contamination and moisture from entering the internal windings and surfaces of the motor. This lost productivity can affect the company’s bottom line. Stainless steel motors can be easily inspected and are more resistant to caustic solutions.

Stainless Steel motors have a longer lifespan.

Using stainless steel motors for pharmaceutical applications is beneficial for several reasons. They are durable, hygienic, and save manufacturers a great deal of money in maintenance costs. In addition, they can withstand high-pressure washdowns without the risk of contamination of the finished product. Stainless steel motors also have a longer lifespan than other materials. These benefits make them a wise investment.

Electric motors generate heat when in operation. Heat increases the pressure inside the motor, which can damage the seal. This excess pressure is relieved through a relief valve. Stainless steel electric motors from HZPT feature an anti-condensation heater that maintains the housing temperature even when the motor is off. This feature also prevents short circuits and corrosion and extends the motor’s life.

Stainless Steel Electric Motors for Sale

Introduces a full line of stainless steel IEC food safety motors fitted with three sizes of stainless steel worm gear reducers designed for harsh washdown conditions in industries where sanitation is critical. The Food Safety series stainless steel AC motors or worm gear motors are particularly suitable for the meat, poultry, fish and dairy industries where severe contamination can occur, which makes our stainless motors the excellent replacement for Baldor stainless steel food safe motors.

To reduce the risk of contamination and the amount of water and chemicals required to sanitize equipment, all food safety products must be easy to clean. The stainless steel electric motors feature smooth, rounded housings that eliminate gaps that could trap food particles and harbor bacteria. Even the nameplates on motors and gears are laser etched to avoid channels and ridges where contaminants can accumulate.

We are one of the best Motors manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Application