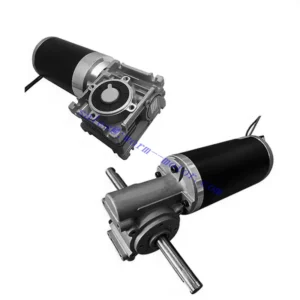

Worm Motor

HIGH QUALITY HIGH PRECISE MANUFACTURER & SUPPLIER

Worm Motor For Sale

-

12v 24v 300w 500w worm geared dc motor

-

12v 24v 48v electric dc worm gear motor with

-

24V DC motor high torque brushed worm gear motor

-

70mm 12V 24V DC Worm Gear Motor For Exhaust Smoke Window

-

Electric Gear Motor 24V 500W 12V Worm Drive Dc Motor

-

High quality worm speed reducer/gear speed motor/worm gear speed reducer gear box gearbox drive

Worm Motor Advantage

High Torque Output

Worm motors are known for their ability to deliver high torque output, making them suitable for applications that require heavy load handling and torque multiplication. They can efficiently transmit power to drive equipment or machinery that requires substantial force.

Precise Speed Reduction

Worm motors provide precise speed reduction capabilities. With their worm gear and worm wheel configuration, they enable fine-tuned speed adjustments, allowing operators to achieve the desired operational speeds for their specific applications. This precision is beneficial in applications that require controlled and accurate motion.

Self-Locking Capability

One of the significant advantages of worm motors is their inherent self-locking property. The design of the worm gear prevents backdriving, meaning that the motor holds position even when not actively engaged. This self-locking feature eliminates the need for additional braking mechanisms, enhancing safety and stability in applications where holding position is critical.

What Is A Worm Motor?

The interaction between the worm gear and the worm wheel enables the conversion of input torque and rotational motion into a different output speed and torque. When the worm rotates, its threads engage with the teeth of the worm wheel, causing the wheel to rotate. The direction of rotation of the worm wheel is perpendicular to the axis of the worm gear.

One distinctive characteristic of worm motors is their self-locking property. Due to the angle of the worm threads, the friction between the worm gear and the worm wheel prevents backward motion or backdriving. This self-locking feature allows the worm motor to hold position without the need for additional braking mechanisms.

Worm motors are commonly used in applications that require high torque output, precise speed reduction, and self-locking capabilities. They find application in various industries, including material handling, lifting equipment, automation, robotics, automotive, and more. The compact design, smooth operation, and versatility of worm motors make them a popular choice for power transmission in a wide range of applications.

How To Maintain The Brake Motor?

Here are some maintenance tips to consider:

Regular Lubrication: Lubrication is essential for the smooth operation of worm motors. Follow the manufacturer’s recommendations regarding the type of lubricant and the frequency of lubrication

Inspect and Clean: Regularly inspect the worm motor for any signs of dirt, debris, or contaminants that may affect its performance.

Check for Wear and Damage: Periodically inspect the worm gear, worm wheel, bearings, and other components for signs of wear, damage, or misalignment.

Tighten Loose Fasteners: Check and tighten any loose fasteners, such as bolts, screws, or clamps, that secure the motor and its components.

Maintain Proper Operating Conditions: Ensure that the worm motor operates within the specified temperature and environmental conditions. Excessive heat, humidity, or exposure to moisture can affect the motor’s performance and lead to premature failure

What is the working principle of Worm Motor?

Here’s a breakdown of the working principle:

Worm Gear: The worm gear is a cylindrical gear with a spiral thread, known as the worm, wrapped around it. The worm resembles a screw, with helical threads cut into its surface. The worm gear is typically driven by an input power source, such as an electric motor.

Worm Wheel: The worm wheel, also called the worm gear wheel or worm wheel gear, is a gear that meshes with the worm. It has teeth that engage with the threads of the worm. The worm wheel is connected to the output shaft of the motor or the driven mechanism that receives the power.

Meshing of Worm and Worm Wheel: When the input power source rotates the worm gear, the threads on the worm engage with the teeth of the worm wheel. As the worm rotates, it causes the worm wheel to rotate as well. The direction of rotation of the worm wheel is perpendicular to the axis of the worm gear.

Speed Reduction: The helical threads on the worm create a mechanical advantage, resulting in a significant reduction in speed between the worm gear and the worm wheel. The number of threads on the worm and the number of teeth on the worm wheel determine the gear ratio and the speed reduction achieved by the worm motor.

Application of Worm Motor

Worm motors are commonly used in conveyor systems to drive the movement of materials or products. They provide the necessary torque to move heavy loads smoothly and can control the speed of the conveyor belt, ensuring efficient material handling in industries such as manufacturing, logistics, and warehousing.

Worm motors are used in various machine tools, such as milling machines, lathes, and grinding machines. They provide precise speed reduction and torque to drive the cutting or shaping mechanisms of these tools. The self-locking property of worm motors ensures stable positioning during machining operations.

Worm motors are widely employed in lifting and hoisting equipment, including cranes, winches, and elevators. Their high torque output and self-locking feature make them well-suited for lifting heavy loads and holding them securely in place. Worm motors ensure safe and controlled vertical movement in construction sites, warehouses, and other industrial settings.

Worm motors find application in automotive systems, including power windows, windshield wipers, and seat adjustment mechanisms. They provide the necessary torque and speed reduction for these motorized components, ensuring smooth and controlled movement.

Blog

WHY CHOOSE US?

We are one of the best worm motor manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!