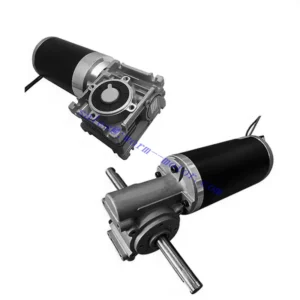

70mm 12V 24V DC Worm Gear Motor For Exhaust Smoke Window

As one of the worm motor manufacturers, suppliers, and exporters of mechanical products, We offer worm motors and many other products.

Please get in touch with us for details.

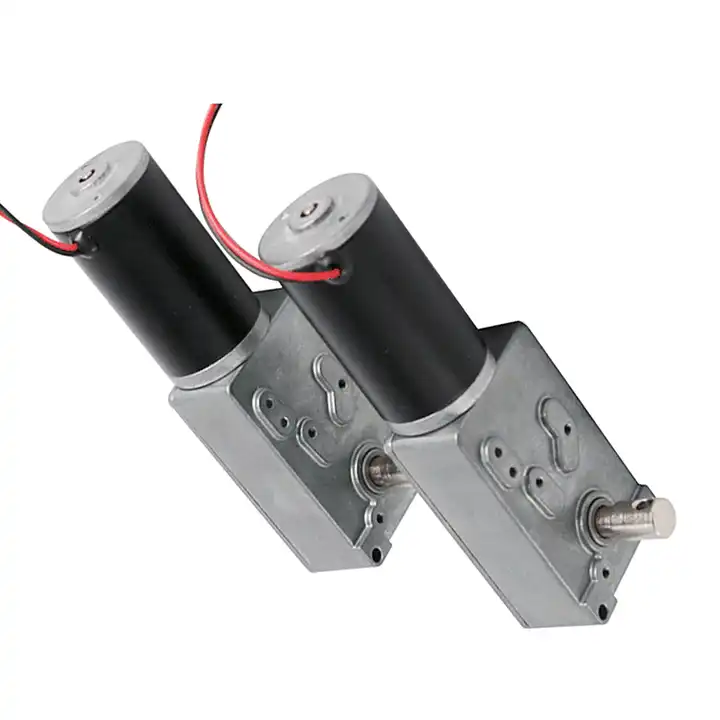

Worm Motor

Our worm motor excels at providing significant speed reduction while multiplying torque output. With its unique worm gear and worm wheel configuration, this motor delivers precise and controlled motion in a wide range of industrial processes. Whether you need to drive heavy loads, operate machinery at low speeds, or achieve accurate positioning, our worm motor ensures reliable and efficient power transmission.

Safety and stability are paramount in many applications, and our worm motor delivers on both fronts. Thanks to its inherent self-locking property, the worm gear prevents backdriving, ensuring that the output shaft holds position even when the motor is not actively engaged. This eliminates the need for additional braking mechanisms and enhances the safety and stability of your equipment or machinery.

With its sliding contact between the worm gear and worm wheel, our worm motor provides smooth and quiet operation. This feature is particularly valuable in applications where noise reduction is crucial or when a smoother motion is desired. You can rely on our worm motor to deliver the performance you need without compromising on comfort or noise levels.

Worm Motor Specifications

|

Torque

|

0.3~15Kgf.cm

|

|

Construction

|

right angle gear motor

|

|

Commutation

|

Brush

|

|

Protect Feature

|

Totally Enclosed

|

|

Speed(RPM)

|

0.5~123rpm

|

|

Continuous Current(A)

|

No Load 40~160mA

|

|

Efficiency

|

IE 1

|

Worm Motor Benefits

1. High Torque Output: Worm motors are known for their ability to provide high torque output, making them suitable for applications that require heavy load handling and torque multiplication. They excel in scenarios where substantial force is needed to drive equipment or machinery efficiently.

2. Precise Speed Reduction: Worm motors are designed to deliver precise and controlled speed reduction. With their worm gear and worm wheel configuration, they allow for fine-tuned speed adjustments, enabling operators to achieve the desired operational speeds for their specific applications.

3. Self-Locking Capability: One of the significant advantages of worm motors is their inherent self-locking property. The design of the worm gear prevents backdriving, meaning that the motor holds position even when not actively engaged. This self-locking feature eliminates the need for additional braking mechanisms, enhancing safety and stability in applications where holding position is critical.

4. Compact and Space-Efficient: Worm motors have a compact design, allowing for easy integration into machinery and equipment with limited space. Their compact size makes them suitable for applications where space constraints are a concern, without compromising on performance and torque output.

5. Smooth and Quiet Operation: Due to the sliding contact between the worm gear and worm wheel, worm motors provide smooth and quiet operation. This characteristic is beneficial in applications where noise reduction is important or when a smoother motion is desired, enhancing overall user experience and comfort.

6. Versatile Application Range: Worm motors find application in various industries and equipment types, showcasing their versatility. They are commonly used in conveyor systems, lifting and hoisting equipment, mixers, agitators, machine tools, automotive applications, and more. This versatility makes worm motors adaptable to different industrial processes and requirements.

7. Energy Efficiency: Worm motors can offer good energy efficiency, especially at higher reduction ratios. By efficiently converting electrical power into mechanical power, they contribute to overall energy savings and operational cost reduction. This efficiency is particularly valuable in applications where power consumption is a concern.

8. Durability and Longevity: Worm motors are known for their robust construction and durability. Engineered with high-quality materials and precision manufacturing, they can withstand demanding conditions, resist wear and tear, and have a longer service life. This durability reduces maintenance requirements and minimizes downtime, maximizing productivity in various industrial settings.

Uses Of Worm Motor

1. Conveyor Systems: Worm motors are widely used in conveyor systems for material handling. They provide the necessary power transmission to move goods along the conveyor belts at controlled speeds, ensuring efficient and reliable transportation in industries such as manufacturing, logistics, and warehousing.

2. Lifting and Hoisting Equipment: Worm motors are commonly employed in lifting and hoisting equipment, including cranes, winches, elevators, and lifts. Their high torque output and self-locking feature make them ideal for lifting heavy loads and maintaining position when the motor is not actively engaged.

3. Mixers and Agitators: Worm motors are utilized in mixers and agitators that require controlled rotational motion. They enable precise speed reduction, allowing operators to achieve the desired mixing or agitation speed for various applications, such as food processing, chemical manufacturing, and pharmaceutical production.

4. Machine Tools: Worm motors play a crucial role in machine tools, including milling machines, lathes, and grinding machines. They facilitate controlled spindle rotation, which is essential for precision machining operations. The self-locking property of worm motors ensures stability during machining processes.

5. Automotive Applications: Worm motors are utilized in various automotive applications, such as windshield wiper systems, power windows, and seat adjustment mechanisms. Their compact size, high torque output, and self-locking capability make them suitable for providing controlled motion in these systems.

Maintenance tips for Worm Motor

1. Regular Lubrication: Lubrication is crucial for the smooth operation of worm motors. Follow the manufacturer's recommendations regarding the type of lubricant and the frequency of lubrication. Apply the appropriate lubricant to the worm gear and other moving parts as specified to reduce friction, prevent wear, and extend the motor's lifespan.

2. Inspect and Clean: Regularly inspect the worm motor for any signs of dirt, debris, or contaminants that may affect its performance. Clean the motor and its surrounding area, removing any accumulated dust or particles that could interfere with the motor's operation. Ensure that the motor is free from obstructions and that the ventilation openings are clear for optimal cooling.

3. Check for Wear and Damage: Periodically inspect the worm gear, worm wheel, bearings, and other components for signs of wear, damage, or misalignment. Look for excessive noise, vibrations, or irregularities during operation, as these may indicate issues that require attention. If you notice any abnormalities, consult the manufacturer's guidelines or seek professional assistance for further inspection and repair if necessary.

4. Tighten Loose Fasteners: Check and tighten any loose fasteners, such as bolts, screws, or clamps, that secure the motor and its components. Vibrations during operation can cause fasteners to become loose over time, potentially compromising the motor's stability and performance. Ensure that all fasteners are properly tightened to maintain the motor's integrity.

5. Maintain Proper Operating Conditions: Ensure that the worm motor operates within the specified temperature and environmental conditions. Excessive heat, humidity, or exposure to moisture can affect the motor's performance and lead to premature failure. Keep the motor's surroundings clean, dry, and adequately ventilated to prevent the accumulation of heat or moisture.

We are one of the best worm motor manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Application